3D Technology

3D Scanning Companies and Business Models

As with the Additive Manufacturing (AM) industry there are key challenges with disruptive technology companies and business models. Although AM as a commercial product really kicked of in 1985 with Stereo Lithographic Apparatus (SLA) systems due to the lack of knowledge in the engineering and entertainment fields it was predominantly sold into niche prototyping applications where a lot of knowledge had to be transferred to the market place through vendors. It was only through exposure to this technology in larger business and academia did this help facilitate a user base and further AM technologies. Interestingly now that AM is well known still businesses selling AM and reverse engineering (RE) services and expertise go out of business readily.

As 3D scanning companies when talking about service delivery are normally amalgamated with AM technology there are some important questions that need to be answered to identify the key challenges faced this field.

Steps taken by the Uninitiated

Many 3D scanning companies and AM service vendors go out of business due to one main mistake. That is, they buy all the toys they can to provide a flexible service. They then realize their customer base is non-existing or to small to yield a profit, loans get called in and they go out of business. Ok, but surely there should be a customer base like any other service industry. Well, there is however things to consider is that large industries buy the equipment or smarter vendors sell services contracts that include the supply of equipment for use onsite. Overtime this can be more profitable especially when consumables are added in to the equation.

What about SME’s such as smaller engineering firms that need small production volumes or one off prototype solutions. Well, most may work with materials and practices they know and fear change, only changing when a new engineer from the AM and RE field enters the company and knowledge transferred on potential time and cost saving when apt.

Freelancers such as model and prototype makers that do not own equipped workshops may outsource if again they have domain knowledge which is ever more prevalent.

3D Scanner Companies either direct or through vendors specifically sell or rent 3D scanners fundamentally as their business model. A company using such technology based on a cost analysis will decide which route to go through to gain access to industrial 3D scanners.

Business Challenges

There is the large question which is understood however seldom asked aside to vendor profitability and that is; to what extent does non-industrial equipment and software cross-over in AM and RE, and that is no easy question. For instance, the freelancer may have room for desktop fused deposition modelling (FDM) or stereo lithographic apparatus (SLA) and use a $300 3D scanner to make cosplay gear or prototypes for Kickstarter companies or aesthetical non-functional forms for fashion businesses along with other decentralized business models. SME’s may also use similar method but have a workshop and potentially specialize in something.

Interestingly there are workshops you can use as a ‘Maker’ that you pay a fee to use, some freelancers may use these for certain activities.

All of this ‘accessibility’ to low-cost technology at the entry level erodes at current SME business models; at least to a point. The reality is that a $300 scanner does not have the accuracy and working ranges nor the commercial software to process effectively commercial output.

What does this all mean!

This means that although AM SME’s offering services bare the burden of vast initial outlay, if their business play is robust enough and can win business over through correct marketing funnels, they do have a place. As such so do 3D Scanning companies due to the symbiosis of the field with the best model of providing repeat services to the customer and not a one-off sell due to the relatively low-price points of the equipment and the majority of the SME’s not using the technology every day.

Thankfully although AM and RE is closely related to each other, 3D scanning companies deals with data not physical parts and due to the advent of Augmented Reality (AR) and Smart Augmented Manufacturing (SAM) growing in the past five years, demand for 3D scanners should markedly increase.

Why? Well 3D scanner offerings will be needed for scanning production line layouts and objects to add items into assembly and maintenance user workflows. This means users would use AR and SAM models through HUD user wearables to work through complex actions on automated production lines. User interactions will be prompted by AI driving requirements and content showing what needs to be done in real time will be displayed to the user as they work. While this all sounds great for reducing unskilled user error causing assemblies needing rework or scrapping it may make 3D scanning companies highly profitable in both unit sales and service provision in the near future depending on strategy implemented.

3D Technology

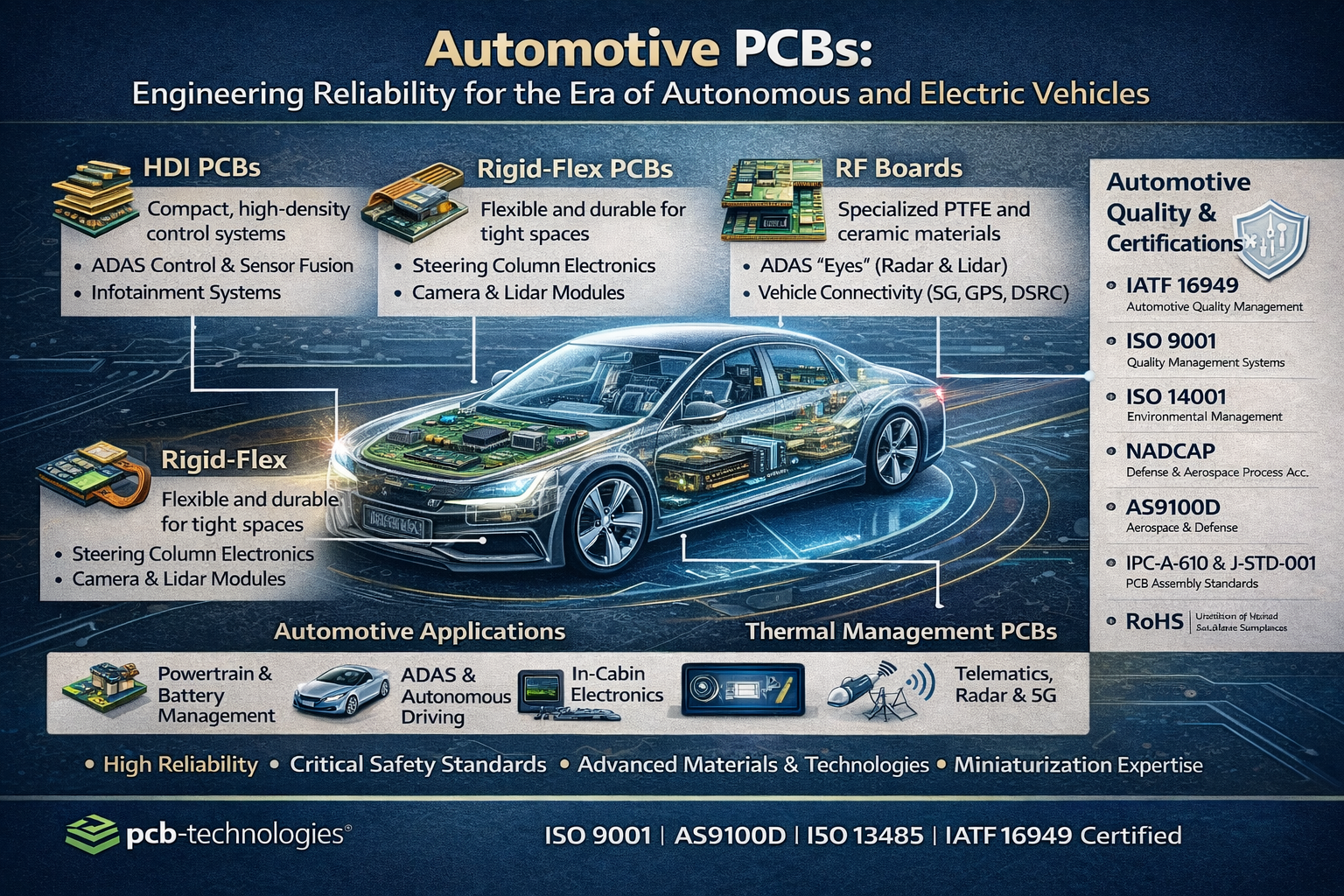

Automotive PCBs: Engineering Reliability for the Era of Autonomous and Electric Vehicles

The modern automobile is no longer simply a mechanical machine. Today’s vehicles — whether a conventional combustion engine car, a battery electric vehicle (BEV), or a fully autonomous system — are deeply sophisticated electronics platforms. Every function, from the engine management system and power steering to the infotainment screen and lidar sensor array, depends on printed circuit boards engineered to perform reliably across extreme temperature ranges, severe vibration, and decades of continuous operation.

Automotive PCBs are among the most demanding products in the electronics manufacturing industry. Failure is not an option: a board that malfunctions in an automotive safety system can have life-altering consequences. This article explores the technology, standards, and applications that define automotive PCBs — and explains why pcb-technologies is a trusted supplier to OEMs and their Electronic Manufacturing Services (EMS) providers worldwide.

Why Automotive PCBs Are Different

Automotive electronics must operate across temperature ranges from -40°C to 85°C or beyond, withstand continuous vibration and mechanical shock, resist moisture and chemical exposure, and maintain full performance for 15+ years of vehicle lifetime. Standard commercial PCBs are not designed for these demands.

The transition to electric and autonomous vehicles has intensified these requirements. New automotive PCB challenges include:

- Power electronics for EV drivetrains: High-current boards managing hundreds of amperes and hundreds of volts for motor inverters and charging systems

- AI processors for autonomous driving: Boards supporting AI accelerators (GPUs, TPUs) with Ball Grid Array packages requiring fine lines, micro-vias, and ultra-low-loss materials for data rates exceeding 25 Gbps

- Lidar and radar modules: High-frequency RF boards requiring specialized PTFE or ceramic-based laminates to maintain signal integrity at millimeter-wave frequencies

- ADAS sensor fusion: Multiple sensor types (radar, lidar, cameras, ultrasonic) integrated through high-density PCB interconnects

- In-cabin electronics: Touchscreens, heads-up displays, driver monitoring systems — all requiring compact, reliable PCBs

Types of PCBs Used in Automotive Applications

pcb-technologies supplies multiple PCB types tailored to the specific demands of automotive electronics:

HDI PCBs (High-Density Interconnect)

HDI PCBs are ideal for automotive control technology, with the ability to pack more functionality into a smaller, lighter footprint. In an industry where size and weight are critical for fuel efficiency and EV range, HDI technology uses micro-vias and fine lines to enable complex, multi-layered designs that would be impossible on conventional boards. pcb-technologies produces HDI boards using the Excellon Cobra Hybrid Laser system and X-VIA technology for precise, void-free via structures.

Rigid-Flex PCBs

Combining the durability of a rigid board with the flexibility of a flex circuit, rigid-flex PCBs are perfect for automotive applications that require a design fitting into tight or irregularly shaped spaces — such as steering column electronics, dashboard assemblies, and camera modules in door mirrors. Rigid-flex eliminates the need for bulky connectors and wire harnesses, reducing both weight and failure points.

RF Boards (Radio Frequency)

Modern vehicles depend on a growing number of RF systems: GPS, V2X (vehicle-to-everything) communications, LTE/5G telematics, radar-based ADAS systems, and keyless entry. RF boards require specialized materials like PTFE or ceramic-based laminates to maintain signal integrity and minimize loss at high frequencies. pcb-technologies has extensive expertise in RF board design and fabrication.

Thermal Management PCBs

Automotive electronics impose significant thermal loads, particularly in power electronics for EVs and high-performance engine control units. pcb-technologies combines materials science, mechanical engineering, and PCB manufacturing technology to effectively dissipate heat. Solutions include embedded copper coins, thermal vias, metal-core boards, and specialized thermally conductive laminates.

Automotive Quality Standards: IATF 16949 and Beyond

The automotive industry operates under some of the strictest quality management requirements in any sector. The key standard is IATF 16949, which defines quality management system requirements specifically for the design, development, production, installation, and service of automotive-related products.

pcb-technologies is certified to IATF 16949, along with a comprehensive suite of additional certifications relevant to automotive customers:

- IATF 16949 — Automotive quality management system

- ISO 9001 — General quality management

- ISO 14001 — Environmental management

- NADCAP — Defense and aerospace process accreditation (for defense-grade automotive programs)

- AS9100 — Aerospace quality management (relevant for autonomous vehicle programs with aerospace-grade requirements)

- RoHS Lead-Free compliance — Fully compliant with automotive RoHS requirements

- IPC-A-610 and J-STD-001 — Assembly standards for all PCBA

pcb-technologies’ Automotive PCB Capabilities

With over 40 years of experience in high-reliability PCB manufacturing, pcb-technologies has built a well-earned reputation in the automotive sector. Key capabilities include:

- Full design services: From initial schematic through DfM, DfT, DfP, DfC, and DfA analysis — optimized for automotive quality and cost targets

- Advanced materials: Including Rogers laminates, PTFE, polyimide, and metal-core for specific automotive performance requirements

- High-current PCBs: Supporting relay and fuse boxes, DC/DC converters, inverters for EV systems, and power/signal integration on one board

- PCBA with advanced packaging: Including Package-on-Package (POP), Micro BGAs, and IC packaging services through the iNPACK division

- Comprehensive testing: ICT, AOI, functionality testing, and vibration testing (S452 Electrodynamic Shaker) — critical for automotive reliability validation

- NPI (New Product Introduction): Fast-tracked NPI services supporting rapid development cycles typical in automotive Tier 1 and OEM programs

The Road Ahead: Automotive Electronics Trends

The automotive PCB market is in the midst of a fundamental transformation, driven by electrification and autonomy:

- Software-defined vehicles: Central computing architectures replacing distributed ECUs, requiring fewer but more powerful, high-density PCBs

- V2X (Vehicle-to-Everything): PCBs supporting 5G NR and DSRC communication modules for cooperative driving

- Integrated AI at the edge: Boards with AI accelerators running machine learning models for real-time visual quality control and autonomous decision-making

- Wearable and in-cabin electronics: Flexible and rigid-flex PCBs enabling new form factors for driver and passenger interfaces

- Battery Management Systems (BMS): High-reliability, high-current boards for EV battery pack management

pcb-technologies is positioned to serve all these emerging requirements, with its iNPACK miniaturization platform and comprehensive design-to-production capability ready for the automotive industry’s next decade.

Learn more about pcb-technologies’ automotive PCB solutions at automotive industry page.

Explore the iNPACK division for advanced packaging in automotive applications at pcb-technologies iNPACK.

Return to the pcb-technologies homepage at pcb-technologies.com.

Frequently Asked Questions

Q: What certifications does pcb-technologies hold for automotive PCBs?

A: pcb-technologies is certified to IATF 16949 (automotive), ISO 9001, ISO 14001, NADCAP, AS9100, and RoHS. All assembly is performed by IPC-A-610 and J-STD-001 certified experts.

Q: What types of PCBs are used in electric vehicles?

A: EV applications use HDI PCBs (for ADAS and control electronics), RF boards (for telematics and radar), thermal management PCBs (for power electronics and battery management), rigid-flex PCBs (for compact form factors), and high-current boards for inverters, converters, and battery management systems.

Q: Why is thermal management critical for automotive PCBs?

A: Automotive electronics generate significant heat, especially in EV power electronics and AI processors. Boards that cannot dissipate heat reliably will fail prematurely — a safety-critical issue. Thermal management solutions include embedded copper coins, thermal vias, metal-core boards, and specialized laminates.

Q: What is IATF 16949 and why does it matter?

A: IATF 16949 is the international automotive quality management standard. It covers design, development, production, installation, and service of automotive-related products. Automotive OEMs and Tier 1 suppliers typically require their PCB manufacturers to be IATF 16949 certified.

Q: Can pcb-technologies produce automotive PCB prototypes as well as production volumes?

A: Yes. pcb-technologies supports the full product lifecycle — from NPI prototype through low, mid, and high volume production — all with the same quality standards and certifications.

3D Technology

How Multispectral Cameras Advance Book Scanning

Multispectral cameras are revolutionizing book scanning by uncovering hidden details, preserving fragile texts, and advancing historical document analysis. These advanced tools capture layers of information invisible to the naked eye, ensuring priceless works are preserved for future generations while providing new insights into our written past.

Imagine revealing hidden texts on a centuries-old manuscript without ever touching the ink. That’s the power of modern imaging technology. Today, book scanning has evolved far beyond simple digital copying—thanks in part to the transformative capabilities of the multispectral camera. These advanced imaging tools are helping archivists, conservators, and researchers uncover layers of information once thought lost to time.

From preserving fragile texts to recovering writings that are invisible to the naked eye, multispectral imaging is revolutionizing the way we digitize, understand, and conserve books.

What Makes Book Scanning So Challenging?

At first glance, scanning a book may seem straightforward: open, place on a scanner, capture. But working with historical or rare volumes is anything but simple. The materials are often fragile, with binding that cannot be fully opened without damage. Inks may have faded over centuries, and pages are sometimes warped, stained, or chemically altered by age and environment.

Standard RGB scanners capture what the human eye sees—red, green, and blue light. While this is fine for a crisp, modern paperback, it fails to capture hidden or degraded content that has faded into the paper over time. Texts erased by water damage or overwritten by later scribes often become unreadable under visible light.

The need for non-invasive, high-fidelity imaging that respects the integrity of these delicate works has pushed researchers toward more sophisticated solutions.

How Multispectral Cameras Work

Multispectral imaging captures data at specific wavelengths across the electromagnetic spectrum, including ultraviolet, visible, and infrared light. Unlike traditional photography, which only captures light as we perceive it, a multispectral camera detects subtle variations in how different materials absorb and reflect light beyond the visible range.

Each layer or pigment in a manuscript may react differently under specific wavelengths. For example, iron gall ink absorbs infrared light, which can make faded handwriting reappear. Organic pigments may fluoresce under UV light, revealing marginalia or annotations invisible in daylight.

This multi-layered approach allows digital imaging specialists to isolate and enhance features hidden beneath the surface—sometimes quite literally.

The Hidden Value of Multispectral Imaging in Book Scanning

One of the most powerful applications of multispectral imaging is text recovery. Historical documents often suffer from fading, overpainting, or even intentional erasure. A multispectral camera can bring back those lost words. By adjusting wavelengths and analyzing spectral differences, researchers can virtually peel back layers of ink or paint.

Multispectral cameras have been used to uncover palimpsests—manuscripts where the original text was scraped off and overwritten. This was common practice in the medieval period when parchment was scarce. Imaging under infrared or ultraviolet wavelengths can isolate the original ink from the newer text, allowing scholars to recover works thought lost.

This technology also plays a role in identifying materials. Certain inks or pigments fluoresce or absorb light differently based on their chemical composition. This can help determine the age and origin of a text, supporting authentication and conservation strategies.

In the realm of illuminated manuscripts and rare books, multispectral imaging reveals artistic techniques and editorial changes. What once lay hidden beneath centuries of aging and retouching becomes visible again, enriching the understanding of the object’s history.

Applications in Restoration and Digital Preservation

Digitization is not merely about creating a digital backup. For cultural institutions, it’s about preserving the experience, the texture, and the historical context of a book. Multispectral imaging helps achieve that goal.

With a multispectral camera, archivists can produce a digital twin of a rare book, capturing more than just the ink on the page. The system can identify discoloration, mold, and water damage—data that informs conservation plans. In some cases, multispectral imaging has revealed insect trails, binding repairs, or even notes from bookbinders left on the inner spine.

In academic research, this depth of imaging allows scholars remote access to detailed replicas, reducing the need to physically handle delicate materials. This not only preserves the book but also democratizes access for institutions without direct access to such collections.

Multispectral vs. Hyperspectral Imaging: What’s the Difference?

The terms multispectral and hyperspectral are often used interchangeably, but there are key differences. Multispectral imaging captures data across a limited number of discrete bands—typically anywhere from 3 to 15. Hyperspectral imaging, by contrast, collects data from hundreds of contiguous spectral bands.

For book scanning purposes, multispectral systems strike a balance between performance and practicality. They are generally more compact, faster, and easier to operate, while still providing the necessary level of spectral detail to uncover hidden or faded content.

Hyperspectral systems may offer finer spectral resolution, but they require more data storage, longer processing times, and more complex calibration. In many archival and preservation settings, the benefits of multispectral imaging outweigh the added complexity of hyperspectral setups.

Choosing the Right Equipment for Cultural Heritage Work

Not all imaging systems are created equal. When selecting a camera system for book scanning, institutions must consider resolution, wavelength range, sensitivity, and software capabilities.

A high-quality multispectral camera designed for cultural heritage work should allow tunable illumination across UV, visible, and IR bands. The camera sensor must be sensitive enough to capture subtle contrasts, and the lens system should minimize distortion, particularly at the edges of curved pages.

Equally important is the software. Advanced processing tools allow operators to isolate channels, adjust contrast, and combine spectral layers to produce meaningful images. The software must also support metadata standards required for digital archiving, ensuring long-term usability and searchability of the files.

Portability and non-contact operation are often critical in environments like libraries or monasteries where the subject cannot be moved or unbound. Systems that support adjustable lighting angles and image stacking also help reduce glare and page curvature.

Challenges and Best Practices in Multispectral Book Scanning

As powerful as multispectral technology is, it’s not without its challenges. Calibration is essential—ambient light, temperature shifts, or misaligned optics can skew results. Most workflows require regular calibration using reference targets to ensure color fidelity and wavelength accuracy.

Lighting must be controlled precisely. Too much UV exposure, for example, can degrade delicate pages. Many systems use pulsed or narrow-band LED lighting to minimize heat and light damage while maintaining illumination consistency.

Stabilizing the book is another critical factor. Scanning should be done with minimal physical stress. Cradles, vacuum tables, or V-shaped book supports are commonly used to hold books gently in place without opening them beyond their structural limits.

Metadata is a final consideration. Multispectral scans produce large volumes of data—often hundreds of megabytes per page. Organizing, labeling, and backing up these files in accordance with international standards is essential for long-term accessibility.

Illuminating the Invisible, One Page at a Time

Multispectral imaging is opening doors once thought permanently closed. Faded poetry, erased philosophies, and hidden marginalia are reemerging into view—not through excavation, but through light.

As libraries, museums, and archives race to digitize and preserve the world’s most precious documents, the value of high-resolution, wavelength-targeted imaging becomes clear. A multispectral camera doesn’t just scan a book—it tells its full story, one invisible layer at a time.

Institutions that embrace these technologies will lead the way in conservation, access, and scholarship. For the historians, linguists, and preservationists of tomorrow, these scans will be the key to unlocking the past.

Reveal centuries of history with modern book scanning systems powered by multispectral imaging.

FAQs on Multispectral Imaging and Book Scanning

- What is a multispectral camera and how is it used in book scanning?

A multispectral camera captures images across different light wavelengths—such as ultraviolet, visible, and infrared—to reveal hidden or faded details in books that aren’t visible to the naked eye. - How does multispectral imaging differ from traditional scanning?

Traditional scanning captures visible light (RGB), while multispectral imaging collects data from specific non-visible wavelengths, allowing it to uncover erased text, watermarks, or pigment changes in old manuscripts. - Why is multispectral imaging important for cultural heritage preservation?

It enables archivists and researchers to digitally recover and preserve texts, annotations, and materials that are at risk of being lost due to aging, damage, or previous erasure. - Can multispectral cameras damage fragile books?

No, they are non-contact and use controlled lighting. Many systems are specifically designed to minimize exposure to UV or heat, making them safe for delicate or ancient materials. - What types of materials benefit most from multispectral book scanning?

Rare manuscripts, parchment texts, palimpsests, and any documents with faded inks or hidden writings benefit greatly from multispectral imaging. - How does multispectral imaging help in text recovery?

It isolates ink and pigment types by analyzing how they react to different wavelengths, allowing hidden, overwritten, or faded text to become readable again. - Is multispectral imaging better than hyperspectral for scanning books?

Multispectral imaging offers a good balance of performance and practicality. It’s typically faster and more manageable for libraries, while hyperspectral provides more data but with added complexity. - What equipment is needed to perform multispectral book scanning?

A multispectral camera, tunable lighting (UV, VIS, IR), stable book cradles, calibration targets, and specialized image processing software are essential components. - Can libraries and archives afford multispectral imaging systems?

While advanced systems can be costly, there are compact and modular solutions becoming more affordable, especially with grant funding or institutional partnerships.

3D Technology

3D Scanner Technology for Android Phones: Unleashing New Possibilities

From capturing family moments to creating stunning architecture designs, the possibilities of 3D scanning technology are limitless. And now, with advanced 3D scanner technology available for Android phones, we’re about to enter a new era of creativity and innovation. In this blog post, we’ll take a closer look at how 3D scanner technology is changing the game for Android users and unlocking exciting new possibilities that were once out of reach. So fasten your seatbelts and get ready to explore the world of 3D scanning on your smartphone!

The rapid advancement of technology has brought us to an era where 3D scanning is no longer confined to specialized equipment. With the advent of 3D scanner technology for Android phones, individuals now have the power to capture three-dimensional objects and environments using their mobile devices. In this article, we will delve into the capabilities and potential applications of this emerging technology, fueled by the integration of 3D structured light technology into the compact form of a mobile phone 3D scanner.

Understanding 3D Scanner Technology for Android Phones

The integration of 3D scanning capabilities into Android phones has been made possible by leveraging the device’s built-in cameras, sensors, and processing power. This development enables users to capture 3D data with ease, transforming real-world objects into digital representations that can be further manipulated or shared.

The Rise of 3D Structured Light Technology

One of the key technologies behind mobile phone 3D scanners is 3D structured light technology. This method involves projecting a pattern of light onto the subject and using the phone’s camera to capture the deformation of the pattern caused by the object’s shape. By analyzing these deformations, the phone’s software reconstructs a detailed 3D model of the subject.

Applications of Mobile Phone 3D Scanners

The integration of 3D scanner technology into Android phones opens up a myriad of possibilities. Here are a few potential applications:

3D Printing and Design: Mobile phone 3D scanners allow users to easily capture physical objects and convert them into digital models that can be modified or replicated using 3D printing technology. This capability empowers designers, hobbyists, and makers to bring their ideas to life with precision and ease.

Virtual and Augmented Reality: With a mobile phone 3D scanner, users can capture their surroundings and create 3D models for virtual or augmented reality experiences. This technology has the potential to revolutionize gaming, architectural visualization, interior design, and other immersive applications.

Documentation and Preservation: Mobile phone 3D scanners provide a convenient way to capture and preserve the details of cultural artifacts, historical sites, or archaeological findings. This technology enables researchers and enthusiasts to create accurate 3D models for documentation, analysis, and virtual exhibitions.

Q&A Section:

How accurate are 3D scans captured using mobile phone scanners?

The accuracy of 3D scans captured by mobile phone scanners can vary depending on factors such as lighting conditions, the quality of the phone’s camera and sensors, and the scanning technique employed. While mobile phone scanners may not match the precision of professional-grade 3D scanners, they still offer impressive results for a wide range of applications, especially for hobbyists and casual users.

Can mobile phone 3D scanners handle large-scale objects or environments?

Mobile phone 3D scanners are more suitable for capturing small to medium-sized objects due to the limitations of their hardware and scanning range. Attempting to scan large-scale objects or environments might result in reduced accuracy or incomplete data capture. For such applications, dedicated 3D scanners with larger scanning ranges would be more appropriate.

What software is required to process and edit 3D scans captured by mobile phone scanners?

Various mobile applications are available for processing and editing 3D scans captured by mobile phone scanners. These apps allow users to align, clean, and refine the captured data, as well as export it in various formats compatible with 3D modeling and printing software.

The integration of 3D scanner technology into Android phones has opened up new creative and practical possibilities for users. With the ability to capture and manipulate 3D models on their mobile devices, individuals now have a powerful tool at their fingertips. From 3D printing enthusiasts bringing their designs to life to architects visualizing their creations in augmented reality, the accessibility of mobile phone 3D scanners is democratizing the world of three-dimensional scanning.

Moreover, the convenience and portability of mobile phone 3D scanners make them ideal for on-the-go scanning needs. Whether you want to capture the intricate details of a unique artifact or document a space for virtual walkthroughs, these scanners provide a user-friendly and versatile solution.

As technology continues to evolve, we can expect mobile phone 3D scanners to become even more sophisticated and capable. The integration of advanced sensors, improved camera technologies, and enhanced processing power will likely lead to higher accuracy and faster scanning speeds. This will further expand the range of applications for mobile phone 3D scanners and empower users to explore new creative horizons.

Additional Resources:

-

3D Technology3 years ago

3D Scanner Technology for Android Phones: Unleashing New Possibilities

-

Business Solutions2 years ago

Understanding A2P Messaging and the Bulk SMS Business Landscape

-

Business Solutions2 years ago

Business Solutions2 years agoThe Power of Smarts SMS and Single Platform Chat Messaging

-

Automotive3 years ago

Automotive3 years agoDSRC vs. CV2X: A Comprehensive Comparison of V2X Communication Technologies

-

Tech3 years ago

On Using Generative AI to Create Future-Facing Videos

-

Business Solutions2 years ago

Business Solutions2 years agoExploring OTP Smart Features in Smart Messaging Services

-

Business Solutions2 years ago

Business Solutions2 years agoLive Video Broadcasting with Bonded Transmission Technology

-

Business Solutions10 months ago

Business Solutions10 months agoThe Future of Healthcare SMS and RCS Messaging